The sensational hop in oil costs over the ongoing years has put a lot of pressure on finding ways to reduce expenses in the manufacturing industry.

Steam is frequently the main supplier of heat to a process making it an asset therefore utilizing steam productively aids in decreasing the operational costs and in so doing creating savings.

For over a quarter of a century now, we have invested in researching on steam systems, putting together an able team that can deliver and associating oursleves with the manufacturer who has a proven energy efficient and emission reducing solution.

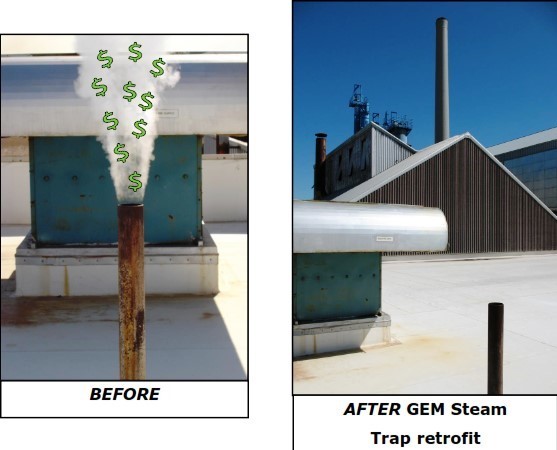

Thermal Energy Int’l. Inc. manufactures the GEM® Steam Trap which steam users can increase profit margins, meet emission regulations and increase production while reducing consumption of fossil fuels. Retrofitting your steam system with GEM® steam traps enables your organization to benefit from:

Thermal Energy Int’l. Inc. manufactures the GEM® Steam Trap which steam users can increase profit margins, meet emission regulations and increase production while reducing consumption of fossil fuels. Retrofitting your steam system with GEM® steam traps enables your organization to benefit from:

Valsteam ADCA Engineering, S.A.is specialized in the design and manufacture of ground breaking products for industrial steam and fluid systems.

Their range of products has been increasing since 1983 and now offers a wide range of solutions for all steam fields such as:

Condensate and compressed air traps

Air eliminators

Pressure reducing valves

Humidity separators

Sight glasses

Heat exchangers

Steam injectors

Control valves

Thermostatic valves

Strainers

Flash vessels

AdcaPure range for clean steam aplicattions

Energy recovery systems and much more.

We represent Valsteam ADCA Engineering, S.A. in Eastern Africa.